Project Retro F-350: Off-Road Drive Shafts

Tom Wood's--best 4x4 drive shaft in the world?

Once you start altering your 4x4’s suspension, it’s almost a given that modifications to the steering and drivelines will be needed. This is especially true anytime you increase the suspension height more than 6 inches. This was the case on our Project Retro F-350.

Our Ford truck had been lifted 12 inches using custom Atlas springs and Bilstein Shocks. The added height dramatically changed the driveline and steering angles. We took care of the steering with a crossover steering system from Off-Road Unlimited, but still needed some help getting power to our front differential.

Because of the added suspension height and gained articulation, the truck would require a longer drive shaft to allow for extra wheel travel in the front. So we contacted Tom Wood’s Custom Drive Shafts from Ogden, UT.

WHY TOM?

Tom Wood is the first name that comes to mind when one thinks about heavy-duty off-road drive shafts. Their quality workmanship is the industry standard. Only the best USA made materials and parts are used on Tom Wood’s Custom Drive Shafts.

Tom has been in the off-road industry for over 20 years, and custom drive shafts are all he does. The man is an avid off-roader and understands the type of predicaments our rigs might find themselves in--on or off the trail.

We met Tom a few years back in Utah and had several conversations with him over the years at Off-Road Expos and the TDS Desert Safari in California. The man knows his stuff.

Some other key factors that set their drive shafts apart are:

• Custom made forged slip yokes that are twice as strong as OE replacements

• MIG welded for a strong and uniform construction

• X spline forged design for greater strength

• Custom CV center housing is made from steel, which is stronger than cast iron used by others

• DOM tubing made in the USA—double the tensile and yield of a comparable cold rolled electric welded tube

• High-speed precision balanced for smooth running drive shaft

MEASURE TWICE, CUT ONCE

When we contacted Tom Wood’s Custom Drive Shafts, we already had decided that we would upgrade from 1310 yolks to 1350s on our front Dana 60 and NP203 transfer case. Project Retro F-350 would be pushing 40-inch BFG Mud Terrain tires around and playing hard in the mud, so any added strength we could get would be gladly taken.

We initially spoke with Josh at Tom Wood’s about our project and dilemma. Josh got us on our way with some key questions to answer in order to get the best drive shaft possible for our set-up. We took some additional measurements to help build our custom off-road drive shaft.

We measured the slope of the t-case, drive shaft, and differential. We also measured the stroke the drive shaft would need; including compressed and extended lengths.

At first this might seems a little daunting, but don’t worry—Tom Wood offers some helpful links to make the measuring process easier.

Tom Wood’s Measuring Guide

http://www.4xshaft.com/MeasuringGuide.pdf

Tom Wood’s Drive Shaft Angle Guide

http://www.4xshaft.com/tech_slopesVSangles.html

After measuring, we came back with the following information and build parts selection:

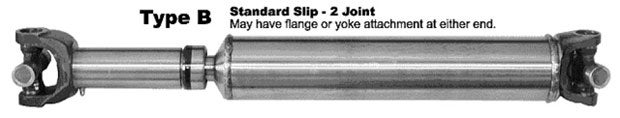

Step 1a: Type B drive shaft

Step 1b: 2.5" tube diameter

Step 1c: Type LT-Spline or XB-spline (2" tube diameter will need to be used for this type of spline and that's ok)

Step 2: 1350 Spicer Yokes (transfercase & differential)

Step 3: Driveshaft length

Standard length 30-1/4"

Compressed length 28"

Expanded length 32"

Step 4: Slopes

Front Differential- 13 degrees

Transfer case – 4 degrees

Front Driveshaft – 25 degrees

We emailed the info back and they were able to make a recommendation on a drive shaft. Tom Wood called us himself and discussed what they could do.

The final product we got from Tom Wood’s Custom Drive Shafts is the following:

Type B drive shaft

• Standard slip

• 2-joint drive shaft

• 2 inch tube-full length extended life spline w/ dust cap

• 1350 series super flex U-Joint @ T-case

• 1350 Series U-Joint @ differential

• Finished length fully compressed (center of joint to center of joint = 27.75”)

• Polish and Clear Coat

We were told that our custom drive shaft would be built and shipped within 24 hours. To our surprise, we received a shiny metal shaft a few days later. We were really impressed that they kept their word — it means a lot, especially in today’s business world.

INSTALLATION

The installation was straightforward. I think it took us longer to read through all the paperwork that came with the drive shaft. By the way…in case you’re reading this Tom, we did read through all the paperwork—thanks for the maintenance and warranty info. We’ll be sure to service the shaft after every big run or 6,000 miles.

Four bolts on each end of the drive shaft and we had a 4x4 truck. The show quality piece adds to the truck’s look, but ultimately, we know that the function is the true reason why we chose Tom Wood’s Custom Drive Shaft.

TEST & PLAY

We drove Project Retro F-350 up to the alpine town of Big Bear, CA for an off-road shakedown. Although the trails were mild, we got to use the 4x4 while crossing a river, crawling over logs and climbing some dirt hills. We didn’t hear or see anything break, and the power to the wheels up front was true. So far, so good.

A few weeks later, Project Retro F-350 drove from L.A. to Oceano Dunes SVRA near Pismo Beach, CA. It was there that 4HI and 4LO were used heavily in the sand and on the dunes. We did some high speed dunning, jumps and climbs. We also came to the rescue of people getting stuck on the beach that needed a tow. There were a lot of those.

The Tom Wood’s Custom Drive Shaft did great. It did not bind, break or wobble after our weekend of fun.

Next we’ll be getting into some serious mud at Azusa Canyon, but unfortunately it’s a bit scarce this time of year. We’ll bring you a mud update later.

All in all, we’re very happy with our Tom Wood’s Custom Drive Shafts. We get compliments from other off-roaders and truck enthusiast all the time. This could very well be “The Best Drive Shaft in the World.”

So if you’re in need of a new or custom drive shaft for your 4x4 or PreRunner, give Tom Wood’s Custom Drive Shafts a call. They’ll build you the best off-road drive shaft and will even guarantee it.

SOURCE:

Tom Wood's Custom Drive Shafts, Inc.

2147 N. Rulon White Blvd.

Suite #103

Ogden, UT 84404

http://www.4xshaft.com/

Your Privacy Choices

Your Privacy Choices