We do things differently here in Arizona. Most folks have spring cleaning after the house or car has been closed up all winter long so they need airing out and cleaning up. In Arizona, because of the heat, our Jeeps are closed up all summer long so we have fall cleaning.

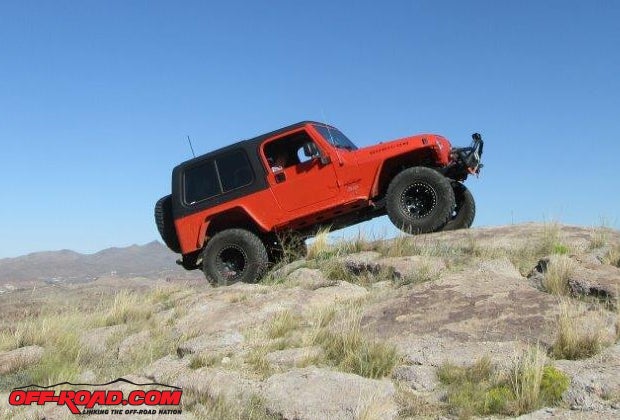

In my case, I like to pull off the hardtop when the summer monsoons wrap upóusually around the middle of Septemberóand I can turn off the A/C and adjust the heater for the cooler evenings. I really like to go lidlessóas my kids call, toplessóand if it werenít so difficult with an LJ, Iíd also have the windshield lying on the hood during trail rides.

In this case, though, with the Arizona daytime sun still being a factor, Iím preparing the Jeep for a Bestop Bikini Top, so the hardtop needs to come off. Up to this time, itís always taken the assistance of a couple friends to remove the top, since Jeep hardtops weigh in excess of 100 pounds. From now on, with the hoist from Hoist Lifts, thatís a thing of the past. Hereafter, my wife and I will be able to remove and reinstall the Jeepís hardtop from Rally Tops.

As youíll see when you visit the website (www.hoistlifts.com/), Hoist Lifts, in addition to the hand-crank design shown here, also offers an electric hoist and a hand hoist without the locking crank. Hoist Lifts will assist you in determining which model will best fit your needs, which in turn also depends on the layout of your garage.

According to Hoist Lifts, the Jeep Wrangler Brake Winch Hard Top Lift, which is the kit installed here, fits all models of Wrangler, regardless of wheelbase dimensions. It sells for $199, and is designed to support your hard top from the center section to the center bottom rear section. The brake winch is mounted on a sidewall stud and then you route the brake winch wire up the wall to the supplied J-hooks and pulleys. The cable is routed across the ceiling through the pulleys that connect to the straps that cradle your Jeepís hardtop to lift it up. And, back down of course. Your Jeep Wrangler hardtop stores just inches from the top of the ceiling. The kit is packaged and assembled in the USA.

Itís a fairly simple install. You have to find the ceiling joists, and the ceiling joists have to be strong enough to hold the pulley on which the top will be stored. See the photos and captions for all the information you need for the install.

Source List

Hoist Lifts

http://www.hoistlifts.com/

Your Privacy Choices

Your Privacy Choices