You’ve increased your Jeep’s tire size for improved ground clearance, and then you lowered its gear ratio (higher number) to take advantage of the taller tires. With the taller tires and lower gears you’ve immediately noticed less stopping power (any tire larger—taller—than a Rubicon’s original 32-inch-diameter tire, needs an improved braking system). The heavier tires require better service brakes to slow and stop them.

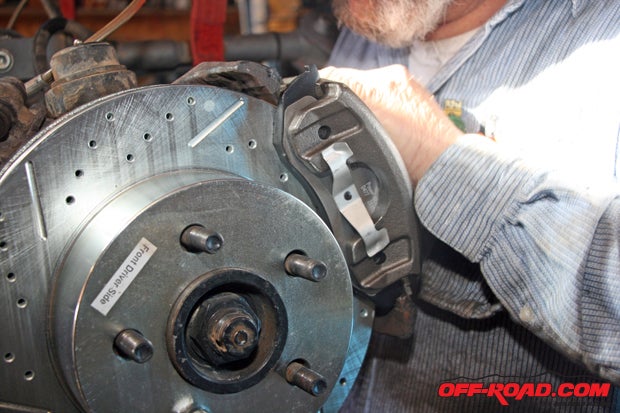

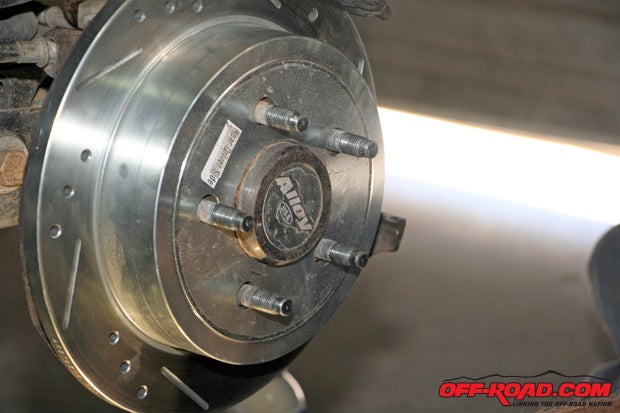

That means if you upgrade your OEM tires (like our 2005 Rubicon: LT245/75R16, 31-inch diameter), the size and weight of the larger tires dictate upgrading your service brakes also. The Summit Racing kits (front #K2152-36; rear #K2197-36), which include new drilled and slotted rotors and brake pads, will take care of that. In fact, when it comes to higher performance braking systems for your Jeeps, Summit Racing is a one-stop shop for all your needs: master cylinders, brake lines, brake fluid, calipers, and shoes.

While some folks say drilled and slotted rotors may have more problems in mud than the flat OEM style rotor, we think the added cooling and drying provided by the holes and slots are well worth it, especially when towing a camping trailer off-road or in heavy traffic. Just remember to clean them after any deep mud traverses.

When you’re planning on towing a 1,500-pound trailer through the famous Rubicon Trail—including the highways in both directions between home and trail—you know you’re going to need the best brakes available for your Jeep. When Jeep engineers convinced the Powers That Be to build the Rubicon, one of the upgrades to a standard Wrangler included disc brakes on all four corners. As most of us know, disc brakes won’t drown out (ever tried to safely negotiate a steep downhill just after a creek crossing with drum brakes?). And due to their design, drum brakes can quickly overheat and lose their stopping power, while disc brakes rarely overheat in non-racing conditions but will cool off rapidly should they become too warm.

All Wrangler-style Jeeps have been equipped with disc brakes on the front axle since the CJ7 was introduced in 1976 (front service brakes do the majority of the braking, so they were upgraded first). As stated above, both axles were equipped with disc brakes with the Rubicon model in ’04, plus they were offered as an option on other Wrangler models. Generally, each disc brake is comprised of a large metal rotor, two flat brake pads, and a hydraulic clamp called a caliper. Slots and holes are usually cast in the rotors to increase cooling effectiveness.

How does a disc brake system work? Pressing the brake pedal forces brake fluid to fill the calipers. Metal pistons inside the calipers are then forced against the back of each brake pad. In each brake, this presses the pad’s friction material against the spinning rotor, quickly slowing the brake rotor and your Jeep.

What are the benefits of disc brakes? They don’t heat up as easily, they cool down more quickly, and water does not make them ineffective. In other words, disc brakes provide better stopping power, making them the clear choice for any style of driving.

While the photos show you several different steps involved in changing out the calipers, rotors and brake pads, we’re not going to take up space here and your time showing you all the steps. You’re better off buying an installation and maintenance manual at your local auto parts store or Amazon. Instead, we’re showing you an overall peek at what it takes to change out all the parts, how to maintain your braking system, and how to service the system.

Bleeding the Brakes

Whenever the hydraulic system is opened—except for removing the master cylinder’s top to check the fluid level—you need to bleed the brakes. Author’s Note: Use the brake fluid called for in your Jeep’s owner’s manual. If you have replaced your brake pads recently—and notice a spongy feel when you engage the brakes—you should consider bleeding your brake system just to be careful. If the brake fluid level drops too low in the master cylinder reservoir, air bubbles can get caught in the lines, reducing the overall strength of the brake fluid column—bleed the brakes. Getting all the air out of the brake fluid system will restore the full strength of the hydraulic brakes.

1. Remove the top of the master cylinder reservoir.

2. If the fluid is murky and not clear, you need to get it out and replace it. Using a clean turkey baster (it’s like a huge eye dropper), suck out as much of the old fluid as you can.

3. After you’ve gotten all the old brake fluid out, clean any sediment out of the reservoir, if accessible, with a clean, lint-free rag and brake cleaner spray. Do not spill any brake fluid on any painted surfaces, it will remove the paint almost immediately.

4. Fill the master cylinder with clean brake fluid and replace the top.

5. Have an assistant pump the brake pedal several times (10 or more).

6. Using a box-end wrench (often 10mm on Jeeps) that fits the bleeder bolt, loosen each bleeder valve in turn, starting with the brake furthest from the master cylinder—in the USA, that’ll be the right rear.

7. Many people, especially professionals, will slide a tube over the bleeder bolt, but most of us just leave it exposed. Using a piece of clear plastic tubing (surgical or aquarium tubing works fine), place the other end in a bottle that you can discard.

8. Refill the master cylinder reservoir with fresh fluid. Keep the master cylinder full during the bleed process, otherwise air might get into system, and replace the top.

9. Have the assistant pump the brake pedal two times and hold it down.

10. Starting with the rear passenger wheel, turn the bleeder bolt to the left one quarter-turn. Old fluid and air will be expelled. When the fluid stops, close the bleeder valve and yell “Pump.”

11. After pumping the pedal twice and holding it, the assistant should yell “OK.” Release the bleeder.

12. Repeat this process until new, clear fluid comes from the bleeder tube. After each wheel or after every five times the brake pedal is depressed, top off the master cylinder reservoir with fresh fluid. Never let the reservoir get too low, or air will be sucked into the master cylinder.

13. Repeat this process at each wheel, moving closer to the master cylinder each time, and ending with the driver’s side front wheel.

14. Finished. Top off the master cylinder one last time.

Breaking in the Brakes

Anytime you install new brake rotors, brake pads, or both, it’s advantageous to break in or “bed in” your new brakes. Bedding in your brakes helps transfer an even layer of brake pad material onto the brake rotor, which assists in smoother brake operation and improved braking power. Having a uniform layer of pad material on the brake rotor is essential to minimizing brake squeal and vibration. For this procedure, you will need a good stretch of road and no traffic. Be safe when you do this and use common sense.

1. Accelerate to 45 miles per hour (mph) and perform three or four medium stops. A medium stop is slightly more aggressive than normal braking, and you don’t need to come to a complete stop for each run. This brings the brake rotors up to temperature so they are not exposed to sudden thermal shock.

2. Next, accelerate to 60 mph and make eight to 10 more aggressive brake applications to pull the Jeep down to 15 mph. For this series, you want to be firm and aggressive, but not to the point where ABS (if equipped) activates and/or the wheels lock up. It’s important to note that you don’t come to a complete stop but rather a semi-stop (about 15 mph). Accelerate quickly back up to 60 mph as soon as you slowed down to your semi-stop.

Author’s Note:

1. The brake pads and brake rotors should be extremely hot at this point and sitting with the pads in one position on the rotors may imprint the pad material onto the surface unevenly. This can cause vibration and uneven braking. You may notice that your brakes will start fading, and sometimes smoke, after the sixth or seventh pass. This fade will eventually stabilize and gradually recess once your brakes have cooled down to normal operating temperatures. Drive carefully as your brakes may feel softer for the next few minutes. Try not to come to a complete stop and find a stretch of road where you can coast for 5-10 minutes, preferably without using your brakes.

2. After the break-in procedure, there may be a light blue tint on your brake rotors as well as a gray film deposit. The blue tint shows that your rotor has reached the appropriate temperature during the bedding process, and the gray film is some of the pad transfer material.

3. Some Jeeps may require two cycles of the bedding-in procedure. This may be the case if you are using old brake rotors with new brake pads, or new brake rotors with old pads. This may also be the case if you don’t think you fully heated up the brakes in the initial bedding procedure. In any case, wait at least 10-15 minutes between each cycle as you don’t want them to overlap.

Adjusting the Parking Brake

If your Jeep’s parking brake is not holding, your problem lies in the adjustment of the drum brakes that serve as the parking brake inside of the rear rotors. There are adjuster ports on the inside of the backing plates of the rear rotors.

1. Remove the rubber plug and use a brake adjusting spoon, the same kind used for adjusting drum brakes (a flat-blade screwdriver can also be used).

2. With the rear wheel suspended, adjust until you can feel a slight drag from the brakes on the wheel when rotating it by hand.

3. Do the same on the other side.

Author’s Note: This will adjust for the wear on the rear parking brake as they are not self-adjusting. If you just tighten up the cable from the hand lever, you are not solving the problem—you stress the cable more to make up the difference for the brakes being out of adjustment—and the brake shoes have to move farther to make contact with the drum’s braking surface.

Sources:

Summit Racing

http://www.summitracing.com/

Your Privacy Choices

Your Privacy Choices